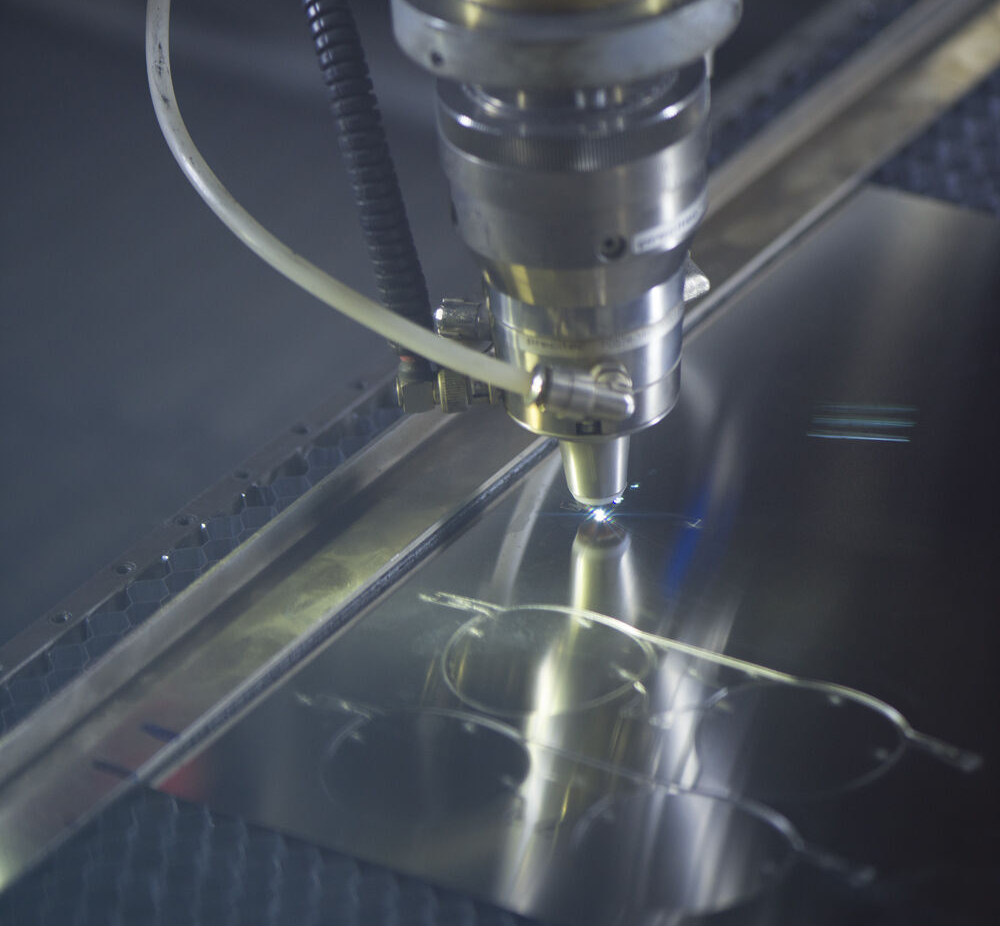

Our metal frames are made from stainless steel consisting of 90% recycled content and 10% raw material to achieve the medical grade quality that our products demand. We source our so-called spring steel exclusively from Alleima, a progressive and purpose-driven company based in Sweden that has been scrap-based and recycling steel for over 100 years. To achieve full circularity, we return our leftover stainless steel as raw material to Alleima’s recycling plant, which uses an electric-arc furnace (EAF) powered almost entirely by fossil-free electricity.

The very first MYKITA collection launched in 2003 was crafted from this highly recycled material. Spring steel offers the optimal blend of malleability and tensile strength required for our eyewear design. Our stainless steel frames are sleek, lightweight, and perfectly adjustable to individual features – this is our signature aesthetic.

Steel production is well known to be harmful to the environment because iron ore is traditionally mined and melted in a ‘blast furnace’ heated by coal. Simultaneously, steel is the most found metal in the scrap metal industry with just under half of the worldwide steel production being recycled. Steel can be reused indefinitely. Recycling is key to the circular economy, helping to protect natural resources.